The printing on knitted sweaters generally uses a combination of glue, water slurry, drawing, hot stamping, and hot drilling. The following is an introduction to several common printing processes:

1. The glue printing process

The glue printing process uses a special chemical gel and dyes to be highly seamlessly mixed. The dye is firmly attached to the fabric through the medium of the gel. The glue printing process overcomes the limitations of water-based printing. Its characteristic is to adapt to printing of various color depths and materials. It can be printed on blended fabrics of cotton, linen, viscose, polyester, nylon, polypropylene, chlorine and various fibers, as well as on leather, artificial leather and other materials. Printing, it can be used for fluorescent printing, inkjet printing, burnout printing, electrostatic flocking printing and other printing processes. The biggest advantage of the glue printing process is that it is widely used, beautiful in color, and high in reduction. However, its printing process is more complicated than the water slurry printing process, and the cost is relatively high.

2. Water slurry printing process

The water slurry printing process is one of the most basic printing processes in the screen printing industry. It can be printed on almost all light background fabrics such as cotton, polyester, linen, etc., and is widely used. Its working principle is similar to dyeing, but the difference is that it “dyes” a certain area of the fabric into the color required for the flower position. Therefore, this process cannot be applied to dark background fabrics. The biggest advantage of the water slurry printing process is that it is widely used, the flower position fastness is very good, and it can print better results at a relatively low price. The limitation of the water slurry printing process is that it cannot be applied to all dark fabrics.

3. Discharging

It is through high temperature to pull out the reactive dyes, and it has no hand feeling and is breathable.

4. Hot stamping and silver hot stamping process

Bronzing and silver bronzing is a traditional binding and beautifying method, which is often used in many paper packaging, but silk-screen bronzing and silver bronzing is a new type of technology. The principle is to add special chemical agents to the printing paste to make the flower position appear particularly beautiful. The color is gold and silver, and the color sample is durable and does not fade. It can be printed on many kinds of fabrics, and the cost is lower than traditional crafts. It is a very ideal printing decoration craft.

5. Hot drilling combination

It’s similar to glue printing, it’s mainly matched together to look better and more popular.

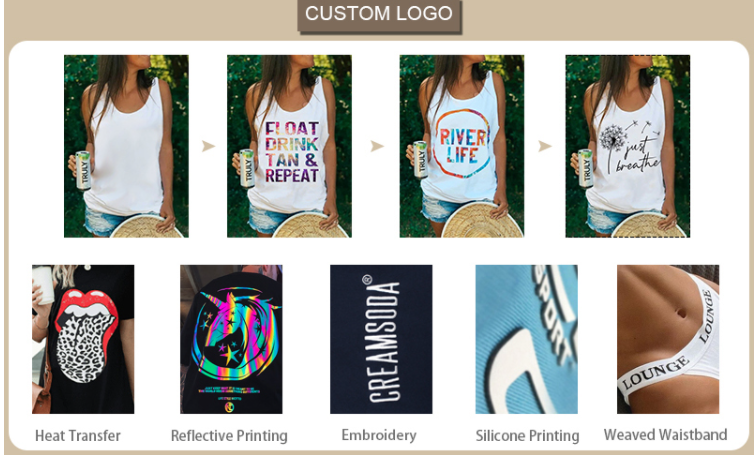

Custom various printing patten